As someone deeply involved in plastic bottle manufacturing, I often encounter clients struggling to choose between different plastic materials. The confusion around safety, durability, and environmental impact can be overwhelming.

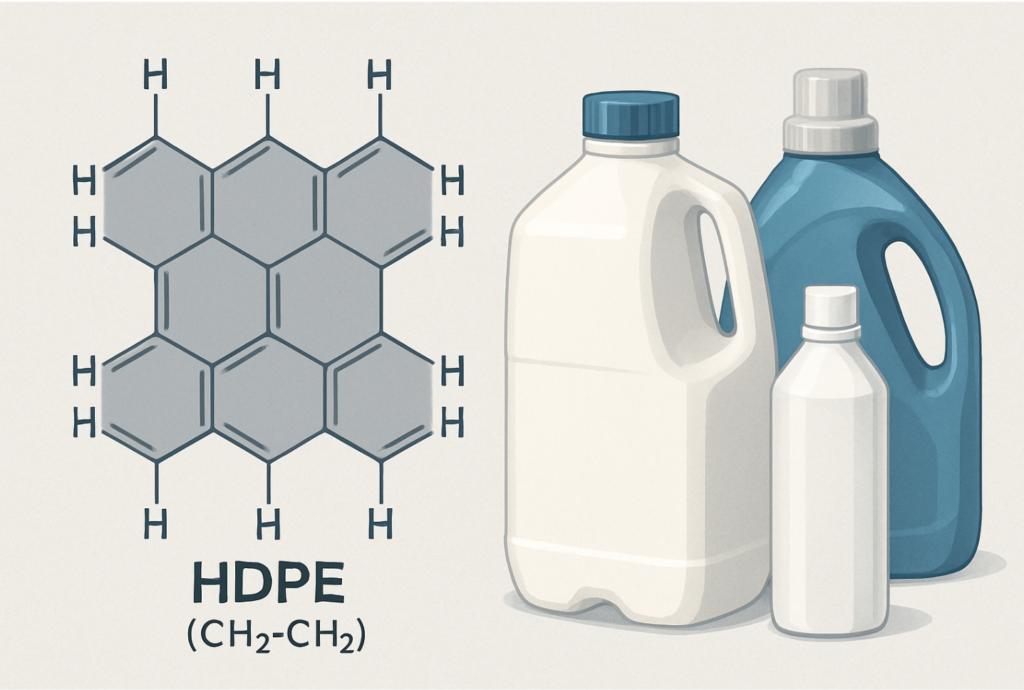

HDPE (High-Density Polyethylene) is a versatile plastic material recognized by recycling code #2. It offers superior durability, chemical resistance, and FDA-approved food-grade safety, making it ideal for diverse packaging applications from milk jugs to industrial containers.

In my 15 years of manufacturing experience, I've seen countless materials come and go, but HDPE remains a constant favorite. Let me share what makes this remarkable material stand out in the packaging industry.

Are HDPE Bottles Safe to Drink From?

Many of my clients, especially those in the beverage industry, express concerns about plastic safety. They worry about chemical leaching and potential health risks associated with plastic containers.

HDPE bottles1 are completely safe for beverages and food storage. The material is FDA-approved2, BPA-free3, and doesn't leach harmful chemicals even under varying temperatures. Its molecular structure remains stable during regular use, making it one of the safest plastic options available.

Let's explore the safety features that make HDPE stand out:

Safety Characteristics

- Non-toxic composition

- Food-grade certification

- Temperature stability (-40°F to 266°F)

- UV resistance

Certification Standards

| Certificate | Region | Purpose |

|---|---|---|

| FDA Approval | USA | Food contact safety |

| EU Food Grade | Europe | Food safety compliance |

| ISO 9001 | Global | Quality management |

| REACH | EU | Chemical safety |

Usage Benefits

- No harmful chemical leaching

- Excellent moisture barrier

- Impact resistance

- Long shelf life

Why is HDPE Used for Bleach Bottles?

After years of supplying bottles to cleaning product manufacturers, I've learned that chemical resistance4 is crucial. Many companies struggle to find packaging that can safely contain harsh chemicals without degradation.

HDPE is the preferred choice for bleach bottles5 due to its exceptional chemical resistance. The material's molecular structure creates an effective barrier against harsh chemicals, preventing degradation and maintaining product integrity even during long-term storage.

Let me break down why HDPE excels in chemical storage:

Chemical Resistance Properties

Molecular Structure Benefits

- Dense molecular packing

- Strong chemical bonds

- Low permeability

- High stability

Performance with Different Chemicals

| Chemical Type | Resistance Level | Storage Duration |

|---|---|---|

| Bleach | Excellent | 2+ years |

| Acids | Very Good | 1-2 years |

| Bases | Excellent | 2+ years |

| Solvents | Good | 1+ year |

Environmental Advantages

- 100% recyclable material

- Lower carbon footprint

- Energy-efficient production

- Reduced plastic waste

Cost Benefits

- Extended product shelf life

- Reduced packaging failures

- Lower transportation costs

- Minimal maintenance requirements

In my experience working with various industries, from pharmaceutical companies to household cleaning manufacturers, HDPE consistently proves its worth. One of our clients, a major cleaning products manufacturer, switched to our HDPE bottles and reported a 40% reduction in packaging-related issues.

HDPE's remarkable combination of safety, durability, and versatility makes it an excellent choice for both consumer and industrial applications. Whether you're packaging beverages, cleaning products, or industrial chemicals, HDPE offers reliable performance and peace of mind.

Need expert guidance on HDPE packaging solutions? Visit www.polybottletech.com or contact me at bellahrcan@hotmail.com to discuss your specific requirements. With our extensive experience and two dedicated production lines, we can help you find the perfect HDPE packaging solution for your products.

-

Explore this link to understand why HDPE bottles are a top choice for safe food and beverage storage, ensuring health and safety. ↩

-

Learn about the significance of FDA approval in food packaging, ensuring consumer safety and compliance with health standards. ↩

-

Discover the importance of BPA-free materials in protecting health and safety in food and beverage storage. ↩

-

Learn about the significance of chemical resistance in packaging to ensure safety and product longevity in various industries. ↩

-

Discover the best materials for bleach bottles to ensure safety and effectiveness in containing harsh chemicals. ↩